Understanding the Tie Back Drill and Its Benefits: A Comprehensive Exploration

The tie-back drill has become a pivotal innovation in the construction industry. This comprehensive exploration delves into every aspect of this tool, its applications, benefits, challenges, and how John Henry Drilling in Charleston, WV, is leading the way.

What is a Tie Back Drill?

What is a Tie Back Drill?

Definition and Purpose

A tie-back drill is specialized equipment used to stabilize structures by anchoring them into the stable ground. This can be vital for various construction applications, from retaining walls to bridge foundations.

Components and Mechanism

- Drill Rig: Houses the machinery.

- Drill Rod: Bores the hole.

- Tieback Anchor: Provides support.

- Grouting System: Secures the anchor.

The mechanism involves drilling, anchoring, grouting, tensioning, and finally connecting the tieback to the structure.

The Detailed Process of Tie Back Drilling

1. Site Analysis and Planning

Soil Testing: Understanding the soil composition.

Engineering Design: Customizing the tieback system.

Regulatory Compliance: Meeting local construction codes.

2. Drilling Phase

Selection of Drill Bit: According to soil type.

Boring the Hole: At a specific angle and depth.

3. Insertion and Grouting

Placing the Anchor: Made of steel or other materials.

Grouting: Filling the void with concrete or other substances.

4. Tensioning and Connection

Load Testing: Ensuring the tieback can handle the stress.

Final Connection: Linking to the structure.

Benefits of a Tie Back Drill

Structural Stability

- Enhancing Safety: Preventing collapses.

- Long-Term Durability: Providing lasting support.

Economic Advantages

- Cost Efficiency: Compared to traditional methods.

- Time-Saving: Speeding up the construction process.

Versatility and Customization

- Adaptable to Various Terrains: From rocky ground to loose soil.

- Tailored Solutions: Meeting project-specific needs.

Environmental Considerations

- Minimal Impact: Protecting surrounding ecology.

- Sustainable Choices: Utilizing eco-friendly materials.

Real-World Applications of Tie Back Drills

1. Retaining Walls

Urban Development: In cityscapes with limited space.

Highway Construction: Supporting roadside embankments.

2. Slope Stabilization

Preventing Landslides: In hilly or mountainous regions.

Coastal Protection: Against erosion.

3. Building Foundations, Bridges, and Dams

Skyscrapers: Enhancing foundation stability.

Large-Scale Infrastructure: Supporting bridges and dams.

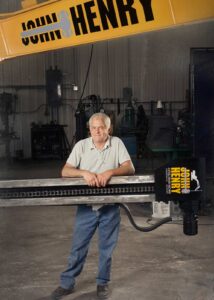

John Henry Drilling in Charleston, WV

Expertise and Experience

- Qualified Team: Skilled in various drilling techniques.

- Decades of Experience: Trusted by many clients.

Technology and Equipment

- Modern Drilling Machines: Ensuring precision.

- Continuous Upgradation: Staying ahead with technology.

- Safety, Quality, and Customer Service

- Safety Protocols: Adhering to industry standards.

- Quality Assurance: Delivering dependable results.

- Client Engagement: Offering personalized service.

Challenges and Considerations

- Geological Challenges: Dealing with unpredictable ground conditions.

- Regulatory Landscape: Navigating local construction laws.

- Economic Factors: Balancing cost and quality.

Embracing the Future with John Henry Drilling

Whether you are an engineer, contractor, or developer, understanding and leveraging the power of tie back drilling can transform your projects. For specialized services and support, don’t hesitate to contact John Henry Drilling. Their expertise transcends ordinary drilling solutions, offering you a partnership in building the future.

What is a Tie Back Drill?

What is a Tie Back Drill?